Home > Smart SPCC-Plan Solution for Spill-Free Oil Changes

If your company stores, handles, or transfers oil, you likely need an SPCC plan. The EPA’s Spill Prevention, Control, and Countermeasure (SPCC) Rule is a federal requirement to prevent oil spills. It is designed to keep oil from reaching navigable waters, shorelines, and surrounding environments. Maintenance shops, fleet operators, and mobile service companies must take proactive steps to prevent leaks and spills before they occur. Read below to learn more about a smart and effective SPCC Plan solution.

Even a small oil leak can create a big problem. Traditional drain plugs often cause spills or drips when they are removed. This results in:

– Contaminated shop floors, service vehicles, or outdoor work sites.

– Extra cleanup costs.

– Environmental and compliance risks.

– Potential fines if your facility or mobile service operation fails an inspection.

For companies creating or updating their SPCC plan, it is essential to find a reliable way to stop leaks. This applies both in the shop and on-site at customer locations.

Under the SPCC Rule, facilities must:

– Develop a written spill prevention plan.

– Implement procedures and best practices to avoid spills.

– Train employees and have the right tools available to reduce risks.

A key part of this is choosing equipment that minimizes the chance of oil escaping into the environment. That’s where Femco comes in.

Mobile service companies face unique challenges when it comes to spill prevention. They often work outdoors or on customer sites, where even a small oil spill can contaminate soil, storm drains, or water sources, leading to expensive remediation costs and potential EPA penalties.

Using a spill-free system like Femco’s Non-Drip plug allows technicians to perform oil changes anywhere without leaving a trace. This not only keeps mobile service operations compliant with SPCC rules, but also improves professionalism and customer satisfaction by keeping the worksite clean.

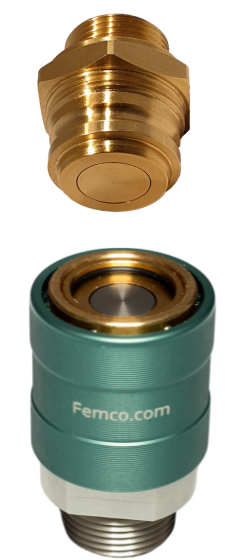

The Femco Non-Drip plug is the cleanest way to drain oil, thanks to its dry-break connection. Unlike conventional drain plugs that can cause spills and drips, the Femco Non-Drip Plug stays in the engine during an oil change. Instead of removing the plug, a Femco coupler is attached, opening the internal valve and allowing oil to flow. This keeps the oil fully sealed when transferring from the engine to an oil pump or waste container.

Its quick-connect design works seamlessly with a suction unit, allowing oil or other fluids to be changed in as little as 30 seconds. This makes the process not only fast and efficient, but also safer and more environmentally responsible, helping maintenance teams maintain a clean workspace while staying compliant with SPCC requirements. This is a must-have and an effective SPCC-Plan solution to help avoid EPA fines.

Femco’s Non-Drip oil drain plugs are available in sizes for all trucks, cars, agricultural, and industrial equipment on the market. These can be paired with a variety of Non-Drip couplers depending on your set up, whether you’re draining with a truck mounted waste oil pump or gravity draining into a bucket. Femco’s experienced team can assist in finding all the right sizes for you or your clients fleet.

Are you looking for a practical and effective SPCC-plan solution for your shop or mobile service fleet? The Femco Non-Drip system makes spill prevention simple, fast, and reliable. You can order the Non-Drip online or contact our team to learn how Femco helps integrate leak-free oil changes into your SPCC plan. This makes compliance easy and stress-free for your operations.